- Home

- About Us

- Business Areas

- Industries Served

- Clients

- Media

- Careers

- Case Study

- Contact

Our turnkey Cylindrical Battery Pack Assembly Line uses advanced automation for precise sorting, welding, and testing.

Read MoreThe Prismatic Battery Pack Assembly Line is a turnkey solution designed with advanced automation for high-speed, precision-driven production.

Read MoreThis solution caters to the growing demand for large-scale energy storage solutions for renewable energy, grid stabilization, and backup power systems.

Read MoreMaestrotech provides software solutions that optimize assembly lines with real-time data analytics, enhanced traceability, and Industry 4.0 integration.

Read More

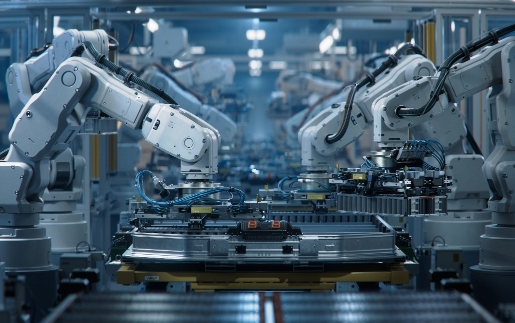

MAESTROTECH offers Turnkey assembly line automation solutions for Customized Battery Packs & Battery Energy Storage Systems (BESS), EV Product Assembly Equipment, Testing Machines, Special Purpose Machines (SPM), and Material Handling Equipment (MHE)—managing every stage from design and development to commissioning.

Our turnkey Cylindrical Battery Pack Assembly Line uses advanced automation for precise sorting, welding, and testing.

The Prismatic Battery Pack Assembly Line is a turnkey solution designed with advanced automation for high-speed, precision-driven production.

This solution caters to the growing demand for large-scale energy storage solutions for renewable energy, grid stabilization, and backup power systems.

Our automated EV charger assembly lines are designed for AC and DC charger units. The solution integrates all stages, from component assembly to final testing,

Maestrotech provides customized automation lines for assembly and testing. Our solutions deliver high efficiency, foolproof poka-yoke mechanisms, and precision.

Dedicated to the assembly of motor controllers, our automation solution ensures quick and accurate assembly of complex systems used in EVs, industrial automation,

Our switch assembly line automation ensures precise assembly of various switch types used across automotive, consumer electronics, and industrial applications.

Maestrotech’s electronic product assembly lines are flexible and scalable, designed to accommodate a wide range of electronic components and products…

Maestrotech provides software solutions that optimize assembly lines with real-time data analytics, enhanced traceability, and Industry 4.0 integration.

The process begins with an inquiry submitted through the website or email, outlining specific requirements, or scheduling a consultation.

A detailed consultation follows, focusing on the specific needs, such as cell types, battery pack specifications, production targets, and additional features like IoT integration or advanced testing capabilities.

A comprehensive proposal is presented, detailing system layouts, recommended technologies, and a clear breakdown of costs and timelines, ensuring complete transparency.

Upon approval, the designs are finalized with detailed engineering reports and simulations, ensuring specifications align with the outlined objectives.

Key components are sourced from leading global suppliers, including Mitsubishi, Panasonic, and Schneider, Trumpf (to check). Simultaneously, manufacturing takes place in a state-of-the-art facility.

Different tools, equipment, and machines integrate with each other via automation and software for seamless functionality within the system.

The system undergoes stringent in-house trial and testing to meet functionality and production goals, ensuring quality, reliability, and optimal performance.

Engineers oversee system installation and integration into new or existing operations. Team training is provided to facilitate smooth operation, maintenance, and adherence to safety protocols.

Support continues post-installation, with services like remote monitoring, troubleshooting, and predictive maintenance. System performance is continually analyzed to implement improvements and scale solutions as requirements grow.

We have had the pleasure of working with Maestrotech on battery pack assembly line, and their commitment to timely delivery has truly impressed us. From the initial stages to project completion, Maestrotech consistently ensures that deadlines are met without compromising on quality.Their efficiency and reliability have made them an invaluable partner in our operations. We highly recommend their services to anyone seeking value for money and outstanding support in their projects

On behalf of Forsee Power, we extend our gratitude to Maestrotech for their service and support throughout our prismatic line project. Your team's professionalism, technical expertise, and prompt responses were key to the smooth progress and timely completion of the project. From planning to final implementation, Maestrotech consistently demonstrated dedication and competence. Your swift and effective handling of challenges enabled us to stay on schedule and meet our goals. Maestrotech has proven to be a reliable, trusted partner, and we deeply value the collaborative spirit and commitment shown throughout this endeavour. We look forward to continuing our successful partnership on future initiatives.